E 7 No. 8 AWG ALUMINUN CLAD STEEL WIRE

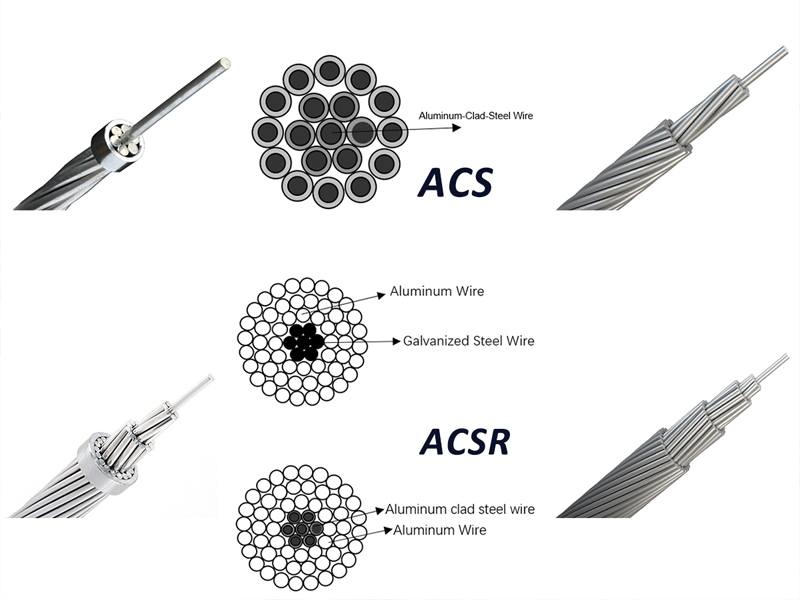

1. ACS SCOPE

This specification aims to define the minimum technical requirements for the conventional aluminum-clad steel shield wire.

2. Aluminum Clad Steel Wire APPLICABLE STANDARDS

ASTM A 153 Zinc Coating (Hot-Dip) on Iron and Steel Hardware

ASTM A 239 Test for Locating the Thinnest Spot in a Zinc (Galvanized) Coating on Iron or Steel Articles by the Preece Test (Copper Sulfate Dip)

ASTM B 193 Test Method for Resistivity of Electrical Conductor Materials

ASTM B 263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

ASTM B 415 Specification for Hard-Drawn Aluminum-Clad Steel Wire

ASTM B 416 Concentric-Lay-Stranded Aluminum-Clad Steel Conductors

IEC 60410 Sampling Plans and Procedures for Inspection by Attributes

IEC 60468 Method of Measurement of Resistivity of Metallic Materials

IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded Conductors

3. Aluminum-clad Steel Shield Wire OPERATING CONDITIONS

3.1 NOMINAL SYSTEM VOLTAGE

The conventional aluminum-clad steel shield wire is used in transmission and sub-transmission lines energized at a nominal voltage of 115 kV.

3.2 ENVIRONMENT

The wire must operate within an ambient temperature range of -20 °C to 80 °C. It must also be capable of withstanding marine and industrial environments.

4. ACS CONDUCTOR GENERAL CHARACTERISTICS AND CONDITIONS

The cables supplied in accordance with this specification shall be entirely new and of recent and proven manufacture. Their entire surface must have a finish completely free from dirt, stains, abrasions, or any type of deformation.

4.1 GENERAL CHARACTERISTICS

Aluminum-clad steel conductors by compression, in accordance with ASTM B 416. These conductors are those in which the cladding is achieved through a compression process.

The manufacturer must indicate in their offer any deviations or discrepancies with respect to what is described in this document and must justify such deviations with supporting documentation based on standards that are being met. Other internationally recognized standards, equivalent to or more stringent than those indicated herein, may be used, provided they comply with the requirements of this Specification. In such cases, one (1) copy of the standards used, in either Spanish or English, must be submitted along with the offer.

Table 1-General Characteristics of ACS-Type Cables

| Property |

Value |

| Gauge |

7No.8 AWG |

| Stranding Direction |

Left-hand lay |

| Cross-sectional Area |

58.56mm² |

| Nominal Outer Diameter |

9.78 mm |

| DC Electrical Resistance at 20℃ |

1.462Ω/km |

| Ultimate Breaking Strength |

70,860 daN |

| Final Modulus of Elasticity |

16,202 daN/mm² |

| Linear Expansion Coefficient |

12.96×10-⁶℃-1 |

| Unit Weight |

3.82 daN/m |

The mechanical characteristics of the wires must comply with Section 5 of the ASTM B 415 standard.

The conductivity percentage of each individual wire must comply with the values established in Table 4 of ASTM B 415. Accordingly, for the 7xNo. 8 AWG cable, the conductivity percentage is 20.3%.

Bare aluminum-clad steel conductors must have concentric stranding and must be manufactured with round aluminum-clad steel wires in accordance with ASTM B 416. The aluminum layer on each wire must have a thickness equal to 10% of the wire's radius, with thicknesses specified in Table 4 of the ASTM B415 standard.

The 7xNo. 8 AWG cable intended for high contamination environments must be greased along its entire length. The grease shall be applied to the inner layers of the cable and shall seal the interstices between wires, both in the inner and outer layers, with a neutral grease (non-reactive to aluminum), chemically pure, and meeting the following physicochemical characteristics:

Table 2-Physicochemical Characteristics of the Grease Used for Aluminum-Clad Steel Shield Wire Protection

| Property |

Result/Value |

Additional Info |

| Application |

Melting |

Approx.160℃ |

| Thickener |

- |

Petrolatums |

| Penetration |

ASTM D-217 |

210±15 |

| Copper Corrosion |

ASTM D-1261 |

Pass |

| Bare Steel Corrosion |

NIBSA NC-04 |

Pass |

| Galvanized and Aluminum Corrosion |

NIBSA NC-048 |

Pass |

| Dropping Point |

ASTM D-566 |

>130℃ |

| Max.Washability |

ASTM D-1264 |

Max.4% |

| Reversibility |

NIBSA NC-01 |

Pass |

| Drip or Sag |

NIBSA NC-02 |

Pass |

| Corrosion Protection (Salt Spray) |

ASTM D-287 |

Pass |

How to Order ACS Alumoweld Aluminum Clad Steel Wire Price

Our team is committed to providing outstanding service before, during, and after the sale. To learn more about our products or to place an order, please contact your sales representative. Email us at info@uni-fibercable.com