Optical Fiber Composite Low Voltage Electric Cable (OPLC)

Optical fiber composite insulated power cable for low voltages (OPLC) is a new type of photoelectric composite cable for low voltage power lines, and has double functions as ordinary low voltage cable and communication cable. The structure of OPLC integrates the fiber and copper wire of transmission and distribution, it uses fiber composite low voltage cable as well as passive optical network technology to achieve fiber to the home (FTTH), undertake the power information collection service of resident users in information intranet, and satisfy the information extranet, multi- network integration service required by intelligent power grid informatization, automation and interactivity.

Product advantages

◆It integrates the fiber and power transmission and distribution cable, avoids the second wiring, and can effectively reduce the cost of construction and network development.

◆Suitable for various business types; strong adaptability; strong expansibility; wide range of product adaptation.

◆Strong mechanical property, such as impact resistance, good pressure resistance, and strong environmental adaptability.

◆Green and extraordinary safety property.

◆Optical unit is compatible with the long working temperature of the power cable.

◆The cost of OPLC is increased by less than 10% of that of traditional low voltage cable, and the cost of FTTH project of OPLC

would be reduced by around 40% of the composite cost of the traditional power cable plus optical cable line project.

Application Places

1 .Electricity Distribution Room to Low voltage feeder box

♦flame retardancy requirement: flame retardant (code: ZR)

♦insulating material: cross-linked polyethylene (code: YJ)

♦sheath material: polyvinyl chloride (code: V)

♦cable category: three- phase four-wire and three- phase and five-wire

♦optical unit model: nonmetal central tube all- dry optical unit (code: XG), nonmetal central tube gel filled optical unit (code: XTG)

2.Low voltage feeder box to user ammeter

♦flame retardancy requirement: flame retardant (code: ZR)

♦insulating material: cross-linked polyethylene (code: YJ), polyvinyl chloride (code:V)

♦sheath material: polyvinyl chloride (code: V)

♦armoring requirement: double copper strip (code: 2)

♦outer sheath requirement: polyvinyl chloride (code: 2)

♦optical unit model: nonmetal central tube all-dry optical unit (code: XG)

♦cable category: single phase three-wire, three-phase four- wire

3.user ammeter to users' indoor

♦flame retardancy requirement: flame retardant (code: ZR), zero halogen low smoke flame retardant category C (code: WDZC)

♦insulating material: polyethylene (code: 丫),polyvinyl chloride (code: V)

♦sheath material:polyethylene (code: 丫 ), polyvinyl chloride (code: V)

♦optical unit model: nonmetal central tube all-dry optical unit (code: XG), bow-type optical unit (code: BG)

Structure parameter

1. Structure chart

3. Cable structure parameters

2. Nonmetal stranded gel filled type photoelectric composite cable (OPLC-YJV-4x150+1x90-0. 6/1-CTG-4B1). Specification

Specification

Optical fiber composite medium-voltages cable, referred to as OPMC, is a new type of optical fiber composite cable used for optical fiber communication and optical fiber access in intelligent power distribution networks. It has the functions of ordinary medium voltage cable and communication optical cable. (OPMC)-based metropolitan area distribution network, realizes the integration of the distribution network communication scheme and the Ethernet passive optical network (EPON) communication networking scheme, which fully improves the communication limitations, optimizes the grid structure, and improves The reliability and power supply quality of the urban core area distribution network, and the construction of a metropolitan area distribution network with the characteristics of "safe and reliable, high-quality, high-efficiency, green, low-carbon, and intelligent interaction" provide technical support.

Features

Applicable

◆ Cable outlet project of power distribution line in a substation.

◆ Overhead transmission line to pipeline line project.

◆ Metropolitan Intelligent Distribution Network Automation Project.

Optical fiber composite insulated power cable for low voltages (OPLC) is a new type of photoelectric composite cable for low voltage power lines, and has double functions as ordinary low voltage cable and communication cable. The structure of OPLC integrates the fiber and copper wire of transmission and distribution, it uses fiber composite low voltage cable as well as passive optical network technology to achieve fiber to the home (FTTH), undertake the power information collection service of resident users in information intranet, and satisfy the information extranet, multi- network integration service required by intelligent power grid informatization, automation and interactivity.

Product advantages

◆It integrates the fiber and power transmission and distribution cable, avoids the second wiring, and can effectively reduce the cost of construction and network development.

◆Suitable for various business types; strong adaptability; strong expansibility; wide range of product adaptation.

◆Strong mechanical property, such as impact resistance, good pressure resistance, and strong environmental adaptability.

◆Green and extraordinary safety property.

◆Optical unit is compatible with the long working temperature of the power cable.

◆The cost of OPLC is increased by less than 10% of that of traditional low voltage cable, and the cost of FTTH project of OPLC

would be reduced by around 40% of the composite cost of the traditional power cable plus optical cable line project.

Application Places

1 .Electricity Distribution Room to Low voltage feeder box

♦flame retardancy requirement: flame retardant (code: ZR)

♦insulating material: cross-linked polyethylene (code: YJ)

♦sheath material: polyvinyl chloride (code: V)

♦cable category: three- phase four-wire and three- phase and five-wire

♦optical unit model: nonmetal central tube all- dry optical unit (code: XG), nonmetal central tube gel filled optical unit (code: XTG)

2.Low voltage feeder box to user ammeter

♦flame retardancy requirement: flame retardant (code: ZR)

♦insulating material: cross-linked polyethylene (code: YJ), polyvinyl chloride (code:V)

♦sheath material: polyvinyl chloride (code: V)

♦armoring requirement: double copper strip (code: 2)

♦outer sheath requirement: polyvinyl chloride (code: 2)

♦optical unit model: nonmetal central tube all-dry optical unit (code: XG)

♦cable category: single phase three-wire, three-phase four- wire

3.user ammeter to users' indoor

♦flame retardancy requirement: flame retardant (code: ZR), zero halogen low smoke flame retardant category C (code: WDZC)

♦insulating material: polyethylene (code: 丫),polyvinyl chloride (code: V)

♦sheath material:polyethylene (code: 丫 ), polyvinyl chloride (code: V)

♦optical unit model: nonmetal central tube all-dry optical unit (code: XG), bow-type optical unit (code: BG)

Structure parameter

1. Structure chart

| Butterfly optical unit photoelectric composite cable (OPLC-YJY- 3x10+BG-0.6/1 T BI+1B4). |

|

2. Optical unit structure parameters

| Item | Unit | Value |

|---|---|---|

| Number of fibers in the cable | Core | Two cores G.652/G.655 |

| Optical unit type | Butterfly pattern | |

| Diameter of strength member | mm | 0.6 |

| Sheathing | Low smoke zero halogen | |

| material | flame retardant polyolefin | |

| Outside diameter of optical unit | mm | 2x3 |

| Weight of optical unit | Kg | 7.1 |

3. Cable structure parameters

| Item | Unit | Corresponding sectional area | Value | Remark |

|---|---|---|---|---|

| Conductor diameter | mm | 10 | 3.8 | The second type copper conductor |

| Number of conductor monofilamen | piece | 10 | 7 | Coarctate round |

| Conductor resistance | Ω/km | 10 | 0.723 | 20℃ |

| Insulation resistance | Ω-X1010 | 10 | 6.17 | Model length 1000cm |

| Insulation thickness | mm | 10 | 0.9 | XLPE |

| Rip cord | piece | 2 | Polyester rip cord | |

| Thickness of outer sheath | mm | 2.3 | Low smoke zero halogen flame retardant polyolefin | |

| Total cable diameter | mm | 18.1 | ||

| Cable weight | kg/km | 550 | ||

| Weight of OPLC | kg/km | 557.1 |

Typical structure

1. Nonmetal central tube all-dry photoelectric composite cable (OPLC-YJV22-4x185-0. 6/1-XG-8B1).2. Nonmetal stranded gel filled type photoelectric composite cable (OPLC-YJV-4x150+1x90-0. 6/1-CTG-4B1).

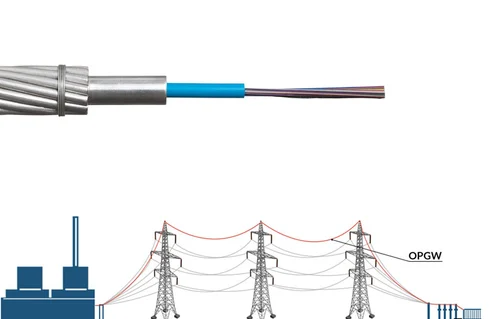

Optical Fiber Composite Medium-voltage Cable OPMC

Optical fiber composite medium-voltages cable, referred to as OPMC, is a new type of optical fiber composite cable used for optical fiber communication and optical fiber access in intelligent power distribution networks. It has the functions of ordinary medium voltage cable and communication optical cable. (OPMC)-based metropolitan area distribution network, realizes the integration of the distribution network communication scheme and the Ethernet passive optical network (EPON) communication networking scheme, which fully improves the communication limitations, optimizes the grid structure, and improves The reliability and power supply quality of the urban core area distribution network, and the construction of a metropolitan area distribution network with the characteristics of "safe and reliable, high-quality, high-efficiency, green, low-carbon, and intelligent interaction" provide technical support.

Features

| ◆ It has strong mechanical properties, such as impact resistance and good pressure resistance, and strong environmental adaptability. ◆ It is suitable for a variety of business types, with strong adaptability, strong scalability, and wide product adaptability. ◆ Composite optical fiber and power transmission and distribution cables avoid secondary wiring, reduce construction costs, and improve pipeline space utilization. |

|

Applicable

◆ Cable outlet project of power distribution line in a substation.

◆ Overhead transmission line to pipeline line project.

◆ Metropolitan Intelligent Distribution Network Automation Project.