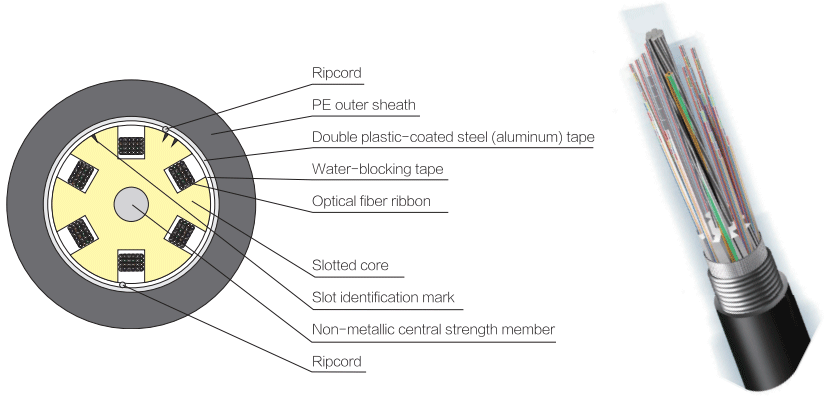

Slotted Core Optical Fiber Ribbon Cable

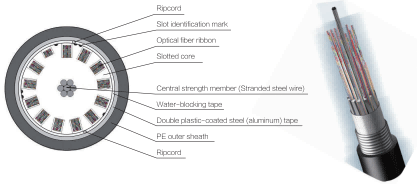

Description•For cables of 300 cores and below: 4 cores or 6cores fiber ribbons are put into the "Z" or "SZ" type HDPE cable core slots, wrap the cable core with water-blocking tape, and a layer of double plastic—coated aluminum or steel tape is armored, then extrude a layer of PE sheath. The central strength member can be FRP or a single wire or stranded wires.

•For cables of above 300 cores: Scores or 8 cores or 12 cores fiber ribbons are put into the"Z" type HDPE cable core slots, wrap the cable core with water-blocking tape, and a layer of double plastic—coated aluminum or steel tape is armored, then extrude a layer of PE sheath. The central strength member can be FRP or a single wire or stranded wires. The maximum fiber capacity is upto 1200 cores.

Characteristics

•Smaller overall diameter and lighter weight with high density of optical fibers compared with the other types of cable with same fiber counts. Or higher fiber count compared with the other types of cable with same cable diameter.

•Excellent performance of crush resistance and impact resistance.

•SAP water-blocking tape adopted to provide whole cross-section water resistance.

•Adopting the full dry-core structure (without fiber jelly and cable gel) to be environmentally friendly, greatly save the preparation time and improve the installation efficiency, and can be protected by air inflation.

•For SZ type slotted core optical fiber cable, the fiber ribbon may be freely taken out from the slot after splitting the sheath, easy and convenient for branching.

•Ripcords are placed between cable core and sheath for easy splitting.

•Can be stranded with signal twisted pairs in the slot if needed.

Application

•Slotted core optical fiber ribbon cable is a new type of high fiber capacity cable, fully meet the requirements of modern communication development (FTTX). It greatly improves the efficiency and convenience of construction, especially applicable to metropolitan area network, access network and junction network.

Slotted Core Optical Fiber Ribbon Cable GYFDGS[A] GYDGS[A] (40-1200 cores)

| SN | Fiber count each ribbon | Fiber count | Direction of rotation | Central strength member |

Max. fiber count per slot | Cable O.D of slot core(mm) | Width of water blocking tape(mm) |

Width of aluminum tape(mm) |

Thickness of sheath (mm) |

Cable O.D (mm) | Cable weight (Kg/KM) | Minimum bending radius | Tension allowed(N) | Crush resistance(N) | |||

| Static | Dynamic | Short term | Long term | Short term | Long term | ||||||||||||

| 1 | 4 | 100 | SZ | 2.3BL | 20 | 9 | 35 | 39 | 1.8 | 14.1 | 161 | 10 times O.D | 20 times O.D | 1500 | 600 | 1000 | 300 |

| 2 | 200 | SZ | 2.3BL | 20 | 12.5 | 35 | 49.5 | 1.8 | 17.6 | 227 | |||||||

◆The slot without any fiber shall be flled with water blocking yarns for water resistance unless otherwise stated or required by customer.

◆Two ripcords will be placed oppositely between the aluminum 1 steel tape and water blocking tape for easy rip-off of the aluminum/steel tape-PE bonded outer sheath.

◆Code of the slot core model name: A: 4 cores fiber ribbon B: 6 cores fiber ribbon C: 8 cores fiber ribbon D: 12 cores fiber ribbon

| SN | Fiber count each ribbon | Fiber count | Direction of rotation | Max. fiber count per slot | Cable O.D (mm) | Cable weight (Kg/KM) | bending radius | Tension allowed(N) | Crush resistance(N) | |||

| Static | Dynamic | Short term | Long term | Short term | Long term | |||||||

| 1 | 4 | 40 | Z | 12 | 10.9 | 110 | 10 times O.D | 20times O.D | 1500 | 600 | 1000 | 300 |

| 2 | 60 | z | 16 | 11.6 | 129 | |||||||

| 3 | 96 | z | 20 | 13.1 | 164 | |||||||

| 4 | 100 | z | 24 | 12.8 | 151 | |||||||

| 5 | 144 | z | 20 | 14.3 | 188 | |||||||

| 6 | 160 | z | 20 | 15.1 | 202 | |||||||

| 7 | 200 | z | 24 | 16.6 | 237 | |||||||

| 8 | 216 | z | 24 | 16.5 | 236 | |||||||

| 9 | 288 | z | 20 | 19.3 | 306 | |||||||

| 10 | 300 | z | 24 | 20.4 | 333 | |||||||

| 11 | 6 | 96 | z | 24 | 12.7 | 158 | ||||||

| 12 | 120 | z | 24 | 13.9 | 174 | |||||||

| 13 | 144 | z | 36 | 14.5 | 190 | |||||||

| 14 | 216 | z | 36 | 17.1 | 243 | |||||||

| 15 | 288 | z | 48 | 17.8 | 265 | |||||||

| 16 | 384 | z | 48 | 20.3 | 333 | |||||||

| 17 | 432 | z | 60 | 21.3 | 372 | |||||||

| 18 | 600 | z | 60 | 23.9 | 450 | |||||||

| 19 | 720 | z | 80 | 26.1 | 530 | |||||||

| 20 | 8 | 400 | z | 80 | 20.1 | 347 | ||||||

| 21 | 600 | z | 80 | 23.1 | 452 | |||||||

| 22 | 1000 | z | 48 | 29.5 | 695 | |||||||

| 23 | 12 | 144 | z | 72 | 15 | 192 | ||||||

| 24 | 288 | z | 96 | 17.3 | 258 | |||||||

| 25 | 360 | z | 108 | 19.1 | 307 | |||||||

| 26 | 432 | z | 84 | 19.8 | 331 | |||||||

| 27 | 504 | z | 96 | 21.6 | 394 | |||||||

| 28 | 576 | z | 108 | 21.6 | 402 | |||||||

| 29 | 648 | z | 120 | 22.3 | 428 | |||||||

| 30 | 720 | z | 108 | 23.3 | 463 | |||||||

| 31 | 864 | z | 108 | 24.6 | 505 | |||||||

| 32 | 1080 | z | 120 | 27.9 | 632 | |||||||

| 33 | 1200 | z | 12 | 29 | 679 | |||||||

♦The slot without any fiber shall be filled with water blocking yarns for water resistance unless otherwise stated or required by customer.

♦Two ripcords will be placed oppositely between the aluminum / steel tape and water blocking tape for easy rip-off of the aluminum/steel tape-PE bonded outer sheath.

♦ Code of the slot core model name: A: 4 cores fiber ribbon B: 6 cores fiber ribbon C: 8 cores fiber ribbon