Introduction

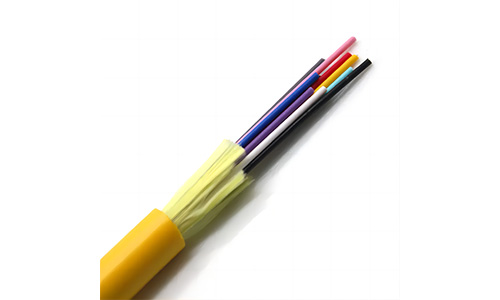

GJFJH(GJYFJH/GJYFJCH) non-metallic strength member, LSZH sheath, non-self-supporting round optical drop cable (or self-supporting round optical drop cable), the optical cable is directly covered with high bonding strength outside the single-mode or multi-mode fiber The tight sleeve material is made of tight sleeve fiber, which uses high-strength aramid as the strengthening element, and is made by extruding a layer of LSZH on the outside. The structure of the self-supporting circular optical drop cable is to increase the metal steel strand suspension wire.

Features

• Tight buffered fibres with excellent strippability

• Good flame-retardant performance

• Aramid yarns providing excellent tensile performance

• Anti-corrosion, water blocking, flame-retardant and environment-friendl

Applications

• Fibre jumper or pigtail

• Indoor riser level and vertical cabling

• Interconnection between instruments and communication equipment

Technical Parameters:

GJFJH(GJYFJH/GJYFJCH) non-metallic strength member, LSZH sheath, non-self-supporting round optical drop cable (or self-supporting round optical drop cable), the optical cable is directly covered with high bonding strength outside the single-mode or multi-mode fiber The tight sleeve material is made of tight sleeve fiber, which uses high-strength aramid as the strengthening element, and is made by extruding a layer of LSZH on the outside. The structure of the self-supporting circular optical drop cable is to increase the metal steel strand suspension wire.

Features

• Tight buffered fibres with excellent strippability

• Good flame-retardant performance

• Aramid yarns providing excellent tensile performance

• Anti-corrosion, water blocking, flame-retardant and environment-friendl

Applications

• Fibre jumper or pigtail

• Indoor riser level and vertical cabling

• Interconnection between instruments and communication equipment

Technical Parameters:

| No. of fibers | Tight buffer material | Strength member | Tight Buffer diameter | Jacket | Short term tension | Short term crush |

| 2~12 | LSZH | Aramid yarns | 0.9±0.05mm | 5.6mm(0.75) | 660 N | 1000N/100mm |

| Test method and Mechanical Characteristic | ||||||

| Tensile Strength | confirm to IEC 794-1-2-E1A | Temperature requirement | Operation | -20℃ - +85℃ | ||

| Crush | confirm to IEC 794-1-2-E3 | Installation | -10℃ - +70℃ | |||

| Impact | confirm to IEC 794-1-2-E4 | Storage/Tran-sportation | -40℃ - +85℃ | |||

| Repeated bending | confirm to IEC 794-1-2-E6 | |||||

| Torsion | confirm to IEC 794-1-2-E7 | Temperature cycling test | confirm to IEC 794-1-F1 | |||

| Flexing | confirm to IEC 794-1-2-E8 | |||||

| Cable bend | confirm to IEC 794-1-2-E11 | Bending Radius | Unloaded | 10 times of outer diameter | ||

| Water penetration | confirm to IEC 794-1-2-F5B | Loaded | 20 times of outer diameter | |||

| XT3002 | Single Mode | XT3003 | Multi mode | |||