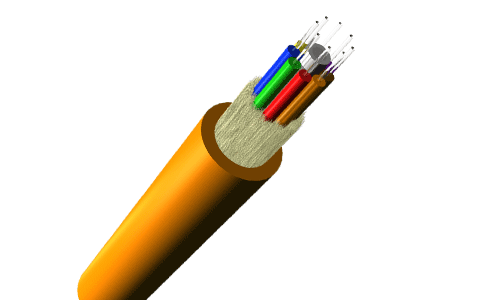

Tight Buffer Fiber Optic Cable

Professional manufacturing for fiber cables and on-demand specs. Request a tight buffer fiber cable quote today.

GET A QUOTE

Description

Applications for Tight Buffer Fiber Optic Cable

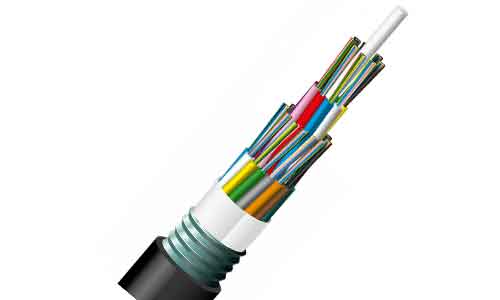

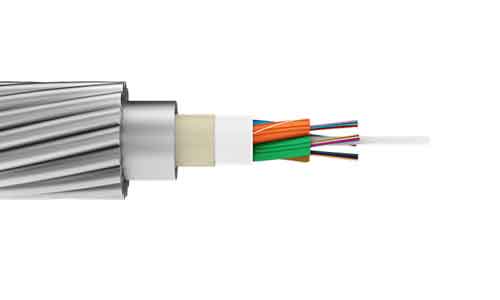

Tight buffer fiber optic cables are popular for its great features, they are generally used indoor for optical distribution, such as fiber patch cord, pigtail, interconnection between equipment or instrument. They are also used for multiple puerpose of distribution between floors in building.

Features & Benefits

Custom Tight Buffer Fiber

Structural parameters

Most Required Tight Buffer Fiber Cable

According to its applications, tight buffer fiber cable can be very useful for indoor optical connection and distribution, but not every tight buffer fiber cable is the same. So if you are planning to buy a tight buffer fiber optic cable, it is best to ask our experienced consultants.

Produces tight buffered fiber cable for:

DISTRIBUTION CABLE – OFNR AND OFNP

BREAKOUT CABLE – OFNR AND OFNP

SINGLE MODE AND MULTIMODE

SIMPLEX AND DUPLEX

OM1, OM2, OM3 OM4, OS2

INDOOR AND INDOOR/OUTDOOR USE

Are you looking for more information on tight buffer fiber or getting an accurate quote?

Get A Quote

Know More About Tight Buffer Fiber Optic Cable

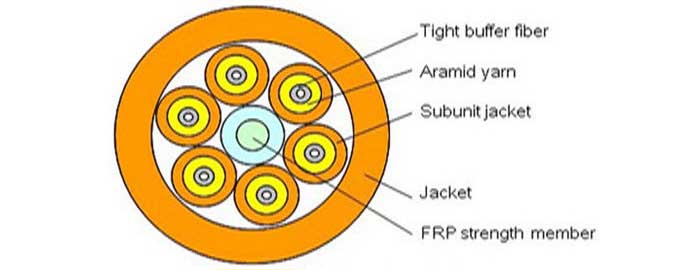

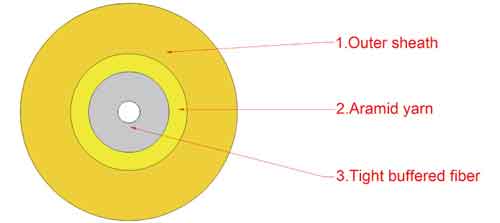

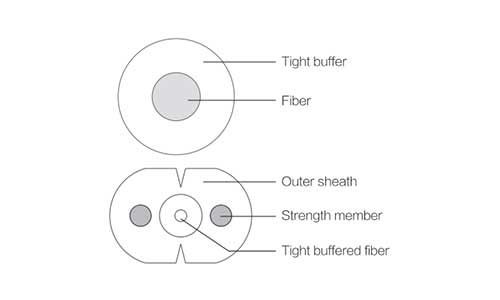

The single-mode or multimode optical fiber with tightly covered secondary structure is called tight buffer fiber or tightly wrapped optical fiber, which is made of plastic (PVC / PVDF / LSZH / Hytrel) directly on the primary cover (UV optical fiber) of bare optical fiber.

The outer diameter of tight buffer fiber is usually 0.6mm and 0.9mm. They are the basic components of various indoor optical cables or tight buffer fiber optic cable. It can also be used alone, the secondary coated with various materials can be directly used as pigtail for the connection of various optical active or passive devices, instrumentation and terminal equipment, etc.

Invisible Optical Cable

Structural parameters

Professional manufacturing for fiber cables and on-demand specs. Request a tight buffer fiber cable quote today.

GET A QUOTE

Description

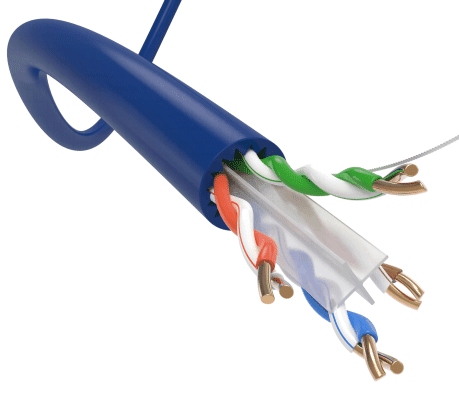

| Tight buffered fiber is made by coating a layer of cushioning material on the discrete fiber. And the cushioning layer is normally the polyvinyl chloride (PVC) or the low smoke zero halogen flame-retardant polyolefin (LSZH). The indoor environment is less hostile and not subject to the extremes seen outdoors. Indoor cables have usually been a tight buffered fiber cable design with either a riser or plenum rating. These cables must conform to National Electric Code (NEC) requirements for riser or plenum applications. |  |

Applications for Tight Buffer Fiber Optic Cable

Tight buffer fiber optic cables are popular for its great features, they are generally used indoor for optical distribution, such as fiber patch cord, pigtail, interconnection between equipment or instrument. They are also used for multiple puerpose of distribution between floors in building.

Features & Benefits

- Tight buffer fiber optic cable designs are typically smaller in size and more flexible. The 900-micron tight buffer fiber is easier to connectorize, and the cable is generally easier to prepare for termination. A tight buffered fiber cable does not typically provide protection from water migration and does not isolate fibers well from the expansion and contraction of other materials due to temperature extremes. Tight buffered fiber cable, often called premise or distribution cables, are ideally suited for indoor cable runs.

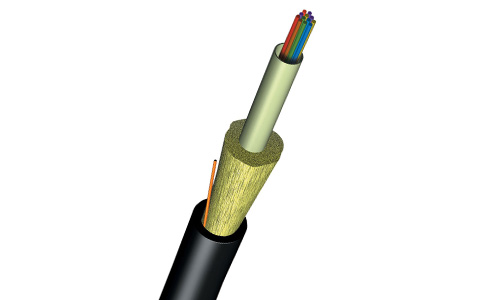

- Tight buffer fiber optic cable is optimal for indoor applications. It is more robust than loose tube fiber cable and is ideally suited for LAN and WAN installations, long indoor runs, direct burial and underwater use. Instead of using gel for water blocking in loose tube cable, tight buffered fiber cable has two layers of coating. The first is plastic, and the second is waterproof acrylate. The latter provides a moisture barrier.

- Tight buffered fiber cable is easier to install than gel-filled loose tube fiber optic cable. Clean up is easier for tight buffer fiber without the gel, and it does not require a fan-out kit for splicing or termination.

- Fast, Easy Installation: Designed with strength members to withstand pulling stress without damage

- No Need for Conduit: Interlocking armor feature provides an additional layer of protection

- Rapid Field Termination: 900 µm tight-buffered cable features a small OD and quickly connects to FX Fusion Splice-On Connectors

- Built for Tough Environments: Indoor/outdoor constructions feature materials that resist UV and moisture exposure

Custom Tight Buffer Fiber

Structural parameters

| Cable diameter (mm) |

Cable weight (km) 一 | Minimum bending radius (mm) | Tensile load (N) | Crush load (N/100mm) | Temperature range (t) | |||

| static | dynamic | Short term Long term | Short term Long term | |||||

| 0.6 | 0.5 | 30 | 60 | 6 | 3 | 500 | 100 | -5℃-+50℃ |

| 0.7 | 0.6 | 30 | 60 | 6 | 3 | 500 | 100 | -10℃ -+60℃笆 |

| 0.9 | 0.9 | 30 | 60 | 6 | 3 | 500 | 100 | -10℃ -+60℃笆 |

Most Required Tight Buffer Fiber Cable

According to its applications, tight buffer fiber cable can be very useful for indoor optical connection and distribution, but not every tight buffer fiber cable is the same. So if you are planning to buy a tight buffer fiber optic cable, it is best to ask our experienced consultants.

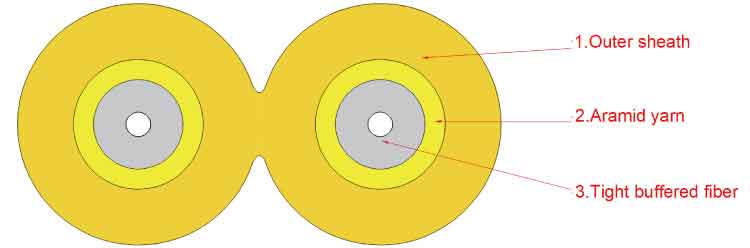

| Simplex Fiber Optic Cable Tight Buffer Indoor Single Mode Cable |  |

| Duplex Tight Buffer Indoor Riser Plenum Distribution Fiber Optic Cable |  |

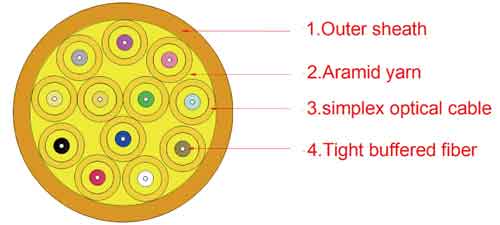

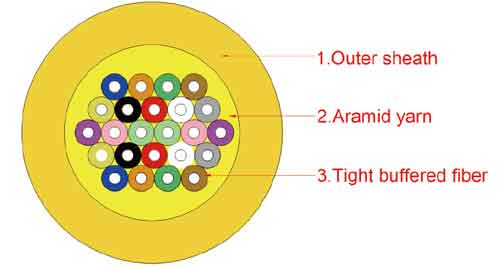

| Optical Fiber Break Out Cable Branched Optical Cable |  |

| Optical Fiber Distribution Cable |  |

Produces tight buffered fiber cable for:

DISTRIBUTION CABLE – OFNR AND OFNP

BREAKOUT CABLE – OFNR AND OFNP

SINGLE MODE AND MULTIMODE

SIMPLEX AND DUPLEX

OM1, OM2, OM3 OM4, OS2

INDOOR AND INDOOR/OUTDOOR USE

Are you looking for more information on tight buffer fiber or getting an accurate quote?

Get A Quote

Know More About Tight Buffer Fiber Optic Cable

The single-mode or multimode optical fiber with tightly covered secondary structure is called tight buffer fiber or tightly wrapped optical fiber, which is made of plastic (PVC / PVDF / LSZH / Hytrel) directly on the primary cover (UV optical fiber) of bare optical fiber.

The outer diameter of tight buffer fiber is usually 0.6mm and 0.9mm. They are the basic components of various indoor optical cables or tight buffer fiber optic cable. It can also be used alone, the secondary coated with various materials can be directly used as pigtail for the connection of various optical active or passive devices, instrumentation and terminal equipment, etc.

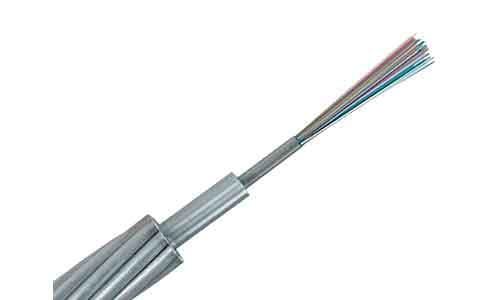

Invisible Optical Cable

| Description Invisible optical cable is made by coating a layer of transparent coating material on the discrete fiber, which is normally the nylon 12 (PA12) with high transparency, high hardness and high bending resistance, or the thermoplastic urethane (TPU). Product application • Indoor integrated wiring • Interconnection of instrument and communication equipment |

|

Structural parameters

| Fiber count | genre | Strength member | Cable diameter (mm) | Cable weight (kg/km) | Minimum bending radius (mm) | Tensile load (N) | Crush load (N/100mm) | Temperature range (℃) | |||

| static | dynamic | Short term | Long term | Short term | Long term | ||||||

| 1 | Invisible optical cable | — | 0.9 | 0.8 | 30 | 60 | 10 | 5 | 1000 | 300 | -5℃ -+50℃ |

| 1 | GJXJH bow type invisible optical cable | Phosphating steel wire | 2.0*3.0 | 9.7 | 30 | 60 | 200 | 100 | 2200 | 1100 | -10℃ -+60℃ |

| 2 | GJXJH bow type invisible optical cable | GFRP/ KFRP | 22*3.6 | 11.8 | 30 | 60 | 80 | 40 | 1000 | 500 | -10℃ -+60℃ |

| 2 | GJXJH bow type invisible optical cable | Phosphating steel wire | 2.2*3.6 | 12.2 | 30 | 60 | 200 | 100 | 2200 | 1100 | -20℃ -+60℃ |