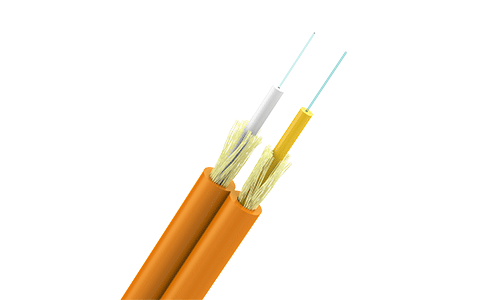

Stainless Steel Tube Mini-cable

Description•The stainless steel tapes are gradually shaped into tube and sealed up by laser beam welding. The optical fibers are led into stainless steel tube by means of initiative unreeling, and the tubes are filled with special fiber jelly in the meantime, then the central tube with fiber of mini-cable comes into being. Afterwards, two parallel steel wires are laid diametrically on both sides of the stainless steel tube as strength members and a layer of compact PE sheath are extruded at the same time, then a stainless steel central tube with parallel steel wires mini-cable is formed.

Characteristics

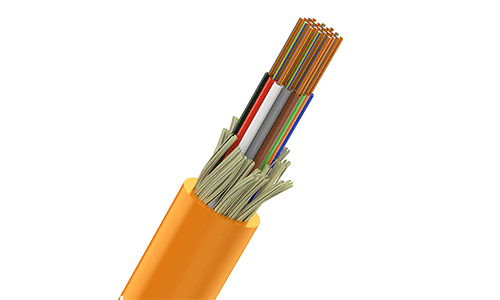

•Small overall diameter (even smaller than that of a pencil), light weight, high fiber capacity.

•Fiber count can be up to 48 cores.

•A compact cable structure, no shrink back for stainless steel central tube, and superior high-low temperature performance.

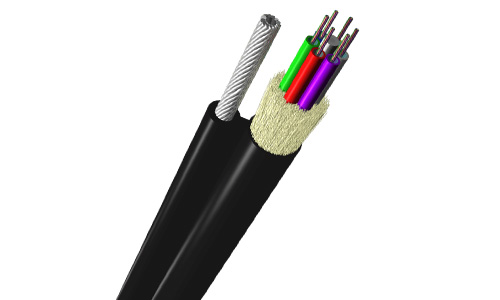

•Excellent performance of rodent^retardant, termite-prevention and crush resistance.

•Superior performance of flame-retardant when flame retardant sheath is applied.

•Fully water resistance for the whole cross-section by filling special fiber jelly in the stainless steel tube.

•Make the best use of the resources of sub-pipes and mini-cable system.

Application

•No need for installation of air-blow but manual ways.

•Applicable for outdoor duct and aerial installation and also indoor use.

•Applicable for metropolitan area network, access network, especially suitable for FTTX construction.

-Applicable for construction and installation in land-forms like crossing indoor and outdoor cement floor, garden lawns, etc.

Stainless Steel Tube Minicable GYXSW (2-48cores)

| Item | Test condition | Typical result I | |

| Temperature range | Operation | / | -4℃ ~ + 7℃ |

| Installtion | / | -5℃: ~ + 50℃: | |

| Storage/transportation | / | - 30℃ ~ + 70℃ | |

| Minimum | Static | / | 10times O.D. |

| bending radius | Dynamic | / | 20times O.D. |

| Tension |

Long term | 600 N | No obvious additional loss on fibers. |

| Short term | 1500 N | Fiber additional loss w 0.05dB/km, no obvious residual additional loss and strain after tension removal. | |

| Crush (N/100mm) |

Long term | 1000 N | No obvious additional loss on fibers. |

| Short term | 2000 N | Fiber additional loss w 0.05dB/km, no obvious residual additional loss and strain after tension removal. | |

| Impact | Hammer weight: 450g Number of impact: 5 times Falling height of Hammer: 1m | No impairment on cable, fiber additional loss < 0.05dB/ kmno obvious residual additional loss and strain. | |

| Repeated bending | Diameter of mandrel: w 30 times O.D Number of cycles: 30 cycles Loading: 150N | No impairment on cable, fiber additional loss w 0.05dB/ kmno obvious residual additional loss and strain. | |

| Torsion | Axial tension: 150N Twist angel: ± 180℃ Twist cycles: 10 cycles Twist length: 1 m |

No impairment on cable, fiber additional loss w 0.05dB/ kmno obvious residual additional loss and strain. | |

| Water penetration | Water height: 1m Duration: 24 hours Sample length: 3m |

No water leakage at the end of cable. | |