Covered Aerial Cables Application

AS/NZS 3675 standard covered conductor is covered with insulation material but without conductor or insulation screens. They must be used in a similar manner to open wire 11 to 33kV

bare overhead systems.

Covered Aerial Cables Classification

There are two main types of covered conductors as follow: CC and CCT. We can provide perfect recommendations on the most suitable installation conditions and fittings for both systems.

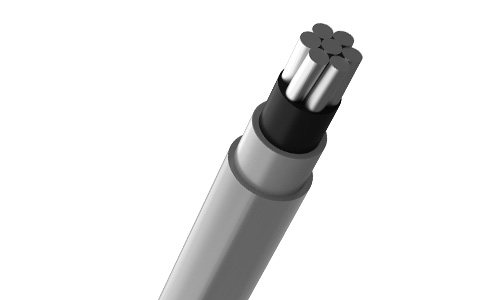

Covered Conductor CC

CC covered conductors have a covering with a minimum average thickness of 2.0mm for use on all working voltages up to and including 19/33kV. CC can withstand intermittent contact with conductive material between phases or to ground. e.g. trees and branches, but should not remain in permanent contact.

1. Conductors:

conductors are available in aluminium, aluminium alloy and aluminium clad steel.

2.Water blocking:

water blocked with a special material meeting all the test requirements of AS/NZS 3675.

3.Covering:

conductors are covered with a track resistant UV stabilised XLPE.

4.Marking:

CC are marked on the external surface with“CC”, logo, year of manufacture, and conductor material. They are also marked with sequential six-digit numbers at 1-metre intervals, with the

lowest number at the inner end of the drum.

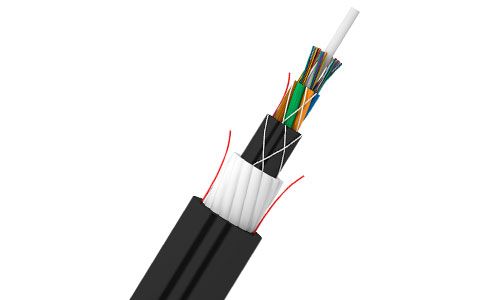

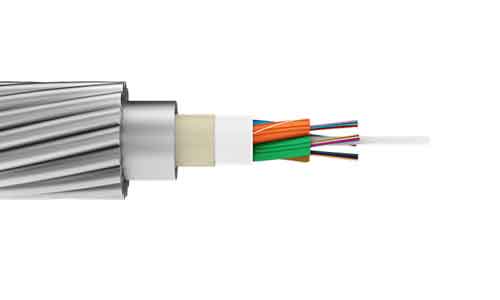

Covered Conductor CCT (FULL THICKNESS COVERING)

CCT covered conductors have a specified thickness of covering for each of the nominated working voltages. While still required to operate under similar principles to a bare wire or CC system, they have electrical and mechanical characteristics which permit them to remain in contact with tree limbs for an extended period dependent on abrasive characteristics of the tree, frequency and strength of prevailing winds and operating temperature.

CCT show better performance in polluted environments. They are suitable for use in spacer cable systems and in the Insulated Unscreened

Conductor (IUC) systems.

1.Conductors:

conductors are available in aluminium, aluminium alloy and aluminium clad steel.

2. Water blocking:

water blocked with a special material meeting the test requirements of AS/NZS 3675.

3.Covering:

conductors are covered with a track resistant UV stabilised XLPE or with an inner layer of non-UV stabilised XLPE.and an outer layer of UV stabilised High Density Polyethylene (HDPE). In the latter case, the average thickness of HDPE is not more than 40% of the specified minimum average thickness, and not less than 1.0mm.

4.Marking:

CCT are marked on the external surface with “CCT", logo, year of manufacture, and conductor material. They are also marked with sequential six-digit numbers at 1-metre intervals, with the lowest number at the inner end of the drum.

Specafications

AS/NZS 3675 Standard Covered Conductor

AS/NZS 3675 standard covered conductor is covered with insulation material but without conductor or insulation screens. They must be used in a similar manner to open wire 11 to 33kV

bare overhead systems.

Covered Aerial Cables Classification

There are two main types of covered conductors as follow: CC and CCT. We can provide perfect recommendations on the most suitable installation conditions and fittings for both systems.

Covered Conductor CC

CC covered conductors have a covering with a minimum average thickness of 2.0mm for use on all working voltages up to and including 19/33kV. CC can withstand intermittent contact with conductive material between phases or to ground. e.g. trees and branches, but should not remain in permanent contact.

1. Conductors:

conductors are available in aluminium, aluminium alloy and aluminium clad steel.

2.Water blocking:

water blocked with a special material meeting all the test requirements of AS/NZS 3675.

3.Covering:

conductors are covered with a track resistant UV stabilised XLPE.

4.Marking:

CC are marked on the external surface with“CC”, logo, year of manufacture, and conductor material. They are also marked with sequential six-digit numbers at 1-metre intervals, with the

lowest number at the inner end of the drum.

Covered Conductor CCT (FULL THICKNESS COVERING)

CCT covered conductors have a specified thickness of covering for each of the nominated working voltages. While still required to operate under similar principles to a bare wire or CC system, they have electrical and mechanical characteristics which permit them to remain in contact with tree limbs for an extended period dependent on abrasive characteristics of the tree, frequency and strength of prevailing winds and operating temperature.

CCT show better performance in polluted environments. They are suitable for use in spacer cable systems and in the Insulated Unscreened

Conductor (IUC) systems.

1.Conductors:

conductors are available in aluminium, aluminium alloy and aluminium clad steel.

2. Water blocking:

water blocked with a special material meeting the test requirements of AS/NZS 3675.

3.Covering:

conductors are covered with a track resistant UV stabilised XLPE or with an inner layer of non-UV stabilised XLPE.and an outer layer of UV stabilised High Density Polyethylene (HDPE). In the latter case, the average thickness of HDPE is not more than 40% of the specified minimum average thickness, and not less than 1.0mm.

4.Marking:

CCT are marked on the external surface with “CCT", logo, year of manufacture, and conductor material. They are also marked with sequential six-digit numbers at 1-metre intervals, with the lowest number at the inner end of the drum.

Specafications

AS/NZS 3675 Standard Covered Conductor

| Conductor size No./mm | Conductor d.c. resistance at 20°C | Conductor a.c. resistance at 80°C | Reactance at 50 Hz (460 mm spacing) | Continuous current carrying capacity | Fault current rating kA for 1 sec.* | Everday working tensionf kN | Maximum working tension (50% MBL) kN | Minimum breaking load kN | Minimum bending radius mm | |||||

| Based on 30°C ambient | Based on 40°C ambient | |||||||||||||

| Ω/km | Ω/km | Ω/km | Still air | 1.0 m/s wind | 2.0 m/s wind | |||||||||

| Alloy 6201 | ||||||||||||||

| 7/2.75 | 0.799 | 0.988 | 0.331 | 125 | 210 | 235 | 110 | 185 | 210 | 3.5 | 1.51 | 5.8 | 11.6 | 200 |

| 7/3.75 | 0.43 | 0.532 | 0.312 | 180 | 300 | 345 | 160 | 270 | 310 | 6.4 | 2.82 | 10.9 | 21.7 | 245 |

| 7/4.75 | 0.268 | 0.331 | 0.297 | 245 | 410 | 465 | 220 | 365 | 415 | 10.3 | 4.52 | 17.4 | 34.8 | 290 |

| 19/3.50 | 0.183 | 0.227 | 0.281 | 315 | 515 | 595 | 280 | 460 | 530 | 15.2 | 6.67 | 25.7 | 51.3 | 340 |

| Alloy 1120 | ||||||||||||||

| 7/2.75 | 0.713 | 0.881 | 0.331 | 130 | 220 | 250 | 115 | 195 | 225 | 3.7 | 1.49 | 4.96 | 9.91 | 200 |

| 7/3.75 | 0.383 | 0.474 | 0.312 | 190 | 320 | 365 | 170 | 285 | 325 | 6.8 | 2.64 | 8.8 | 17.6 | 245 |

| 7/4.75 | 0.239 | 0.296 | 0.297 | 260 | 430 | 485 | 230 | 385 | 435 | 11 | 4.07 | 13.6 | 27.1 | 290 |

| 19/3.50 | 0.163 | 0.202 | 0.281 | 330 | 545 | 625 | 295 | 485 | 560 | 16.2 | 6.26 | 20.9 | 41.7 | 340 |

| TECHNICAL PERFORMANCE CHARACTERISTICS FOR COVERED CONDUCTORS (CCT) | ||||||||||||||

| Conductor size No./mm | Conductor d.c. resistance at 20°C | Conductor a.c. resistance at 80°C | Reactance at 50 Hz (460 mm spacing) | Continuous current carrying capacity | Fault current rating kA for 1 sec.* | Everday working tensionf kN | Maximum working tension (50% MBL) kN | Minimum breaking load kN | Minimum bending radius mm | |||||

| Based on 30°C ambient | Based on 40°C ambient | |||||||||||||

| Ω/km | Ω/km | Ω/km | Still air | 1.0 m/s wind | 2.0 m/s wind | |||||||||

| 11 kv covered conductor Alloy 6201 | ||||||||||||||

| 7/3.75 | 0.43 | 0.532 | 0.312 | 185 | 295 | 330 | 165 | 265 | 295 | 6.4 | 2.82 | 10.9 | 21.7 | 285 |

| 7/4.75 | 0.268 | 0.331 | 0.297 | 245 | 390 | 440 | 220 | 350 | 395 | 10.3 | 4.52 | 17.4 | 34.8 | 330 |

| 19/3.50 | 0.183 | 0.227 | 0.281 | 315 | 500 | 560 | 280 | 445 | 500 | 15.2 | 6.67 | 25.7 | 51.3 | 380 |

| 22 kV covered conductor Alloy 6201 | ||||||||||||||

| 7/3.75 | 0.43 | 0.532 | 0.312 | 185 | 285 | 315 | 165 | 255 | 280 | 6.4 | 2.82 | 10.9 | 21.7 | 350 |

| 7/4.75 | 0.268 | 0.331 | 0.297 | 245 | 375 | 420 | 220 | 335 | 375 | 10.3 | 4.52 | 17.4 | 34.8 | 395 |

| 19/3.50 | 0.183 | 0.227 | 0.281 | 315 | 475 | 530 | 280 | 425 | 475 | 15.2 | 6.67 | 25.7 | 51.3 | 445 |

| 33kv covered conductor Alloy 6201 | ||||||||||||||

| 7/3.75 | 0.43 | 0.532 | 0.312 | 185 | 270 | 295 | 165 | 240 | 265 | 6.4 | 2.82 | 10.9 | 21.7 | 425 |

| 7/4.75 | 0.268 | 0.331 | 0.297 | 245 | 360 | 400 | 220 | 320 | 355 | 10.3 | 4.52 | 17.4 | 34.8 | 470 |

| 19/3.50 | 0.183 | 0.227 | 0.281 | 315 | 455 | 505 | 280 | 405 | 450 | 15.2 | 6.67 | 25.7 | 51.3 | 520 |

| XLPE covered aerial cables Alloy 1120 conductors | ||||||||||||||

| Conductor size No./mm | Conductor d.c. resistance at 20°C | Conductor a.c. resistance at 80°C | Reactance at 50 Hz (460 mm spacing) | Continuous current carrying capacity | Fault current rating kA for 1 sec.* | Everday working tensionf kN | Maximum working tension (50% MBL) kN | Minimum breaking load kN | Minimum bending radius mm | |||||

| Based on 30°C ambient | Based on 40°C ambient | |||||||||||||

| Ω/km | Ω/km | Ω/km | Still air | 1.0 m/s wind | 2.0 m/s wind | |||||||||

| 11kv covered conductor Alloy 1120 | ||||||||||||||

| 7/2.75 | 0.713 | 0.881 | 0.331 | 130 | 215 | 240 | 115 | 190 | 215 | 3.7 | 1.49 | 4.96 | 9.9 | 230 |

| 7/3.75 | 0.383 | 0.474 | 0.312 | 190 | 315 | 345 | 170 | 280 | 310 | 6.8 | 2.64 | 8.8 | 17.6 | 285 |

| 7/4.75 | 0.239 | 0.296 | 0.297 | 26() | 415 | 470 | 230 | 370 | 420 | 11 | 4.07 | 13.6 | 27.1 | 330 |

| 19/3.50 | 0.163 | 0.202 | 0.281 | 330 | 525 | 595 | 295 | 470 | 530 | 16.2 | 6.26 | 20.9 | 41.7 | 380 |

| 22 kV covered conductor Alloy 1120 | ||||||||||||||

| 7/2.75 | 0.713 | 0.881 | 0.331 | 135 | 205 | 225 | 120 | 185 | 200 | 3.7 | 1.49 | 4.96 | 9.9 | 300 |

| 7/3.75 | 0.383 | 0.474 | 0.312 | 190 | 295 | 330 | 170 | 265 | 295 | 6.8 | 2.64 | 8.8 | 17.6 | 350 |

| 7/4.75 | 0.239 | 0.296 | 0.297 | 260 | 400 | 440 | 230 | 355 | 395 | 11 | 4.07 | 13.6 | 27.1 | 395 |

| 19/3.50 | 0.163 | 0.202 | 0.281 | 330 | 505 | 560 | 295 | 450 | 500 | 16.2 | 6.26 | 20.9 | 41.7 | 445 |

| 33kv covered conductor Alloy 1120 | ||||||||||||||

| 7/2.75 | 0.713 | 0.881 | 0.331 | 135 | 195 | 215 | 120 | 175 | 190 | 3.7 | 1.49 | 4.96 | 9.9 | 385 |

| 7/3.75 | 0.383 | 0.474 | 0.312 | 195 | 285 | 315 | 175 | 255 | 280 | 6.8 | 2.64 | 8.8 | 17.6 | 425 |

| 7/4.75 | 0.239 | 0.296 | 0.297 | 260 | 380 | 420 | 230 | 340 | 375 | 11 | 4.07 | 13.6 | 27.1 | 470 |

| 19/3.50 | 0.163 | 0.202 | 0.281 | 330 | 480 | 530 | 295 | 430 | 475 | 16.2 | 6.26 | 20.9 | 41.7 | 520 |

| * Initial temperature 80°C, final temperature 210°C, constant K = 83.0 for alloy 6201 and 88.4 for alloy 1120. f 13% MBL fbr alloy 6201 and 15% MBL for alloy 1120. | ||||||||||||||