Medium Voltage Covered Conductors upto 36 KV

Medium Voltage Covered Conductors are developed to improve the reliability of the distribution of electricity. The concept of covered conductor has proven to be extremely functional and reliable. It consists of a conductor surrounded by a covering made of insulating material as protection against accidental contacts with other covered conductors and with grounded parts such as tree branches, etc. Medium voltage covered conductors are produced in voltage rating between 6.6KV to 33KV.

Suitable for AC high-voltage overhead power lines. Provide protection against accidental contact with other life covered overhead conductors and with grounded parts. Since these cables are unscreened they are not touch proof and shall be treated as bare conductors in respect to electric shock.

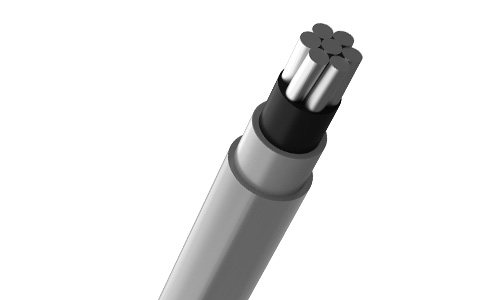

Construction

1 | Bare alloy aluminium conductor (AlMgSi), round stranded compressed (RM). Longitudinally watertight by dry fifi lling.

2 | Core insulation (XLPE, black, UV resistant)

Data

Standard: EN 50397-1

Rated voltage: 20 kV

Test voltage: 20 kV/50 Hz

Temperature range: laying temperature: min. –20 °C

operating temperature: –40 °C to +80 °C

conductor temperature: max. +80 °C

short-circuit temperature: max. +130 °C/5 s

Bending radius (min.): 18 x ∅ of cable

Medium Voltage Covered Conductors are developed to improve the reliability of the distribution of electricity. The concept of covered conductor has proven to be extremely functional and reliable. It consists of a conductor surrounded by a covering made of insulating material as protection against accidental contacts with other covered conductors and with grounded parts such as tree branches, etc. Medium voltage covered conductors are produced in voltage rating between 6.6KV to 33KV.

CCX WK 20 kV

ApplicationSuitable for AC high-voltage overhead power lines. Provide protection against accidental contact with other life covered overhead conductors and with grounded parts. Since these cables are unscreened they are not touch proof and shall be treated as bare conductors in respect to electric shock.

Construction

1 | Bare alloy aluminium conductor (AlMgSi), round stranded compressed (RM). Longitudinally watertight by dry fifi lling.

2 | Core insulation (XLPE, black, UV resistant)

Data

Standard: EN 50397-1

Rated voltage: 20 kV

Test voltage: 20 kV/50 Hz

Temperature range: laying temperature: min. –20 °C

operating temperature: –40 °C to +80 °C

conductor temperature: max. +80 °C

short-circuit temperature: max. +130 °C/5 s

Bending radius (min.): 18 x ∅ of cable

| New marking Number of cores x nominal CroSS section (mm²) |

Old marking Number of cores x nominal CrosS section (mm²) |

Max. conductor resistance (Ω/km) |

Min. breaking load of conductor strand (kN) |

Current rating in air¹) (A) |

Outer diameter (mm)ca. |

Total weight (kg/km)ca. |

| CCX WK 20 kV | ||||||

| 34-AL3 | 1x35 RM | 1.047 | 9.64 | 169 | 11.9 | 175 |

| 49-AL3 | 1x50 RM | 0.7 | 13.87 | 210 | 13.3 | 225 |

| 66-AL3 | 1x70 RM | 0.528 | 18.44 | 255 | 14.7 | 280 |

| 93-AL3 | 1x95 RM | 0.372 | 26.14 | 320 | 16.7 | 375 |

| 117-AL3 | 1x120 RM | 0.297 | 32.79 | 365 | 18.1 | 450 |

| 147-AL3 | 1x150 RM | 0.237 | 41.23 | 425 | 19.8 | 560 |

CCST W 10-52kV

Description

CCST is a round stranded, non-compacted covered overhead line . The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor. This increases the reliability and service life of the covered conductor by preventing water from penetrating the conductor and causing corrosion . The longitudinally water blocked conductor and the three extruded layers are made in one and the same process for the best quality and performance .

Standards EN 50397- 1

Construction

Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of PE

* Outer layer of UV- and tracking resistant HDPE

* Colors - Green, Gray or Black

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

For special requests, we can also design customized solutions.

CCST is a round stranded, non-compacted covered overhead line . The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor. This increases the reliability and service life of the covered conductor by preventing water from penetrating the conductor and causing corrosion . The longitudinally water blocked conductor and the three extruded layers are made in one and the same process for the best quality and performance .

Standards EN 50397- 1

Construction

Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of PE

* Outer layer of UV- and tracking resistant HDPE

* Colors - Green, Gray or Black

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

| Minimum bending radius | 15xD (10xD final installation) |

| Recommended minimum conductor temperature during installation | -20°C |

| Maximum continuous conductor temperature | +70°C |

| Product [-] |

Area [mm2] |

Construction [-] |

Nom. Outer diameter [mm] | Weight [kg/km] |

| CCST 1x62 ACSR | 62 | 1+6 x 3,37mm | 15,4 | 335 |

| CCST 1x99 ACSR | 99 | 1+6 x 4,25 mm | 18,1 | 495 |

| CCST 1x99 AAAC | 99 | 7 x 4,25 mm | 18,1 | 422 |

| CCST 1x159 AAAC | 157 | 19 x 3,26 mm | 21,6 | 637 |

| CCST 1x241 AAAC | 241 | 19 x 4,02 mm | 25,4 | 922 |

| CCST 1x329 AAAC | 329 | 37 x 3,37 mm | 28,8 | 1244 |

CCSX W 10-52kV

Application

CCSX is a round stranded, non-compacted covered overhead conductor. The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor.

This increases the reliability and lifespan of the covered conductor by preventing water from penetrating the conductor and causing corrosion.

The longitudinally waterproof conductor and the three extruded layers are made in one and the same process for the best quality and function.

The outer sheath is UV protected.

Covered conductor is available as ACSR, ACSC and AAAC.

Covered conductor is manufactured and tested according to standard EN 50397-1 or SS 42 414 64.

Construction

* Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of XLPE

* Outer layer of UV- and tracking resistant XLPE

* Colors - Gray or Black

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

CCSX is a round stranded, non-compacted covered overhead conductor. The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor.

This increases the reliability and lifespan of the covered conductor by preventing water from penetrating the conductor and causing corrosion.

The longitudinally waterproof conductor and the three extruded layers are made in one and the same process for the best quality and function.

The outer sheath is UV protected.

Covered conductor is available as ACSR, ACSC and AAAC.

Covered conductor is manufactured and tested according to standard EN 50397-1 or SS 42 414 64.

Construction

* Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of XLPE

* Outer layer of UV- and tracking resistant XLPE

* Colors - Gray or Black

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

| Minimum bending radius | 15xD (10xD final installation) |

| Recommended minimum conductor temperature during installation | -20°C |

| Maximum continuous conductor temperature | +80°C |

| Product [-] |

Area [mm²] |

Construction [-] |

Nom.Outer diameter [mm] |

Weight [kg/km] |

| CCSX 1x62 ACSR | 62 | 1+6×3,37mm | 154 | 335 |

| CCSX 1×99 ACSR | 99 | 1+6×4,25 mm | 181 | 495 |

| CCSX 1x99 AAAC | 99 | 7×4,25 mm | 181 | 422 |

| CCSX 1x159 AAAC | 157 | 19×3,26 mm | 216 | 637 |

| CCSX 1×241 AAAC | 241 | 19×4,02 mm | 254 | 922 |

| CCSX 1x329 AAAC | 329 | 37×3,37 mm | 288 | 1244 |

CCSX W 10-52kV Hybrid

Application

CCSX Hybrid is a round stranded, non-compacted covered overhead conductor. The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor.

This increases the reliability and lifespan of the covered conductor by preventing water from penetrating the conductor and causing corrosion.

The longitudinally waterproof conductor and the three extruded layers are made in one and the same process for the best quality and function.

The outer sheath is UV protected.

Construction

Covered conductor is available as ACSR, ACSC and AAAC.

Standard color - Gray.

Can also be made into customized solutions.

Covered conductor is manufactured and tested according to standard EN 50397-1 or SS 42 414 64.

* Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of XLPE

* Outer layer of UV- and tracking resistant HDPE

* Color - Gray

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

For special requests, we can also design customized solutions.

Conductor (MVCC) is becoming as one of the best replacement of Over Head Bare Conductor (ACSR) and Aerial Bunched cable in power transmission and distribution system in some part of the world. The uses of Covered Conductor which is similar like SAC (Space Arial Bunch Cables) are seen in South Korea, Japan, Iran, Myanmar and some parts of Australia. It has a very successful journey so far.CCSX Hybrid is a round stranded, non-compacted covered overhead conductor. The conductor is longitudinally water blocked with extruded polymer between each layer in the conductor.

This increases the reliability and lifespan of the covered conductor by preventing water from penetrating the conductor and causing corrosion.

The longitudinally waterproof conductor and the three extruded layers are made in one and the same process for the best quality and function.

The outer sheath is UV protected.

Construction

Covered conductor is available as ACSR, ACSC and AAAC.

Standard color - Gray.

Can also be made into customized solutions.

Covered conductor is manufactured and tested according to standard EN 50397-1 or SS 42 414 64.

* Conductor - ACSR, ACSC, AAAC

* Extruded longitudinal water blocking

* Extruded inner semi-conductive layer

* Insulation of XLPE

* Outer layer of UV- and tracking resistant HDPE

* Color - Gray

* Voltage class, U(Um) - 10(12), 20(24), 30(36) and 52kV

| Minimum bending radius | 15xD (10xD final installation) |

| Recommended minimum conductor temperature during installation | -20°C |

| Maximum continuous conductor temperature | +80°C |

| Product [-] |

Area [mm²] |

Construction [-] |

Nom.Outer diameter [mm] |

Weight [kg/km] |

| CCSX 1×25 ACSC HYBRID | 25 | 7×2,12mm | 130 | 253 |

| CCSX 1x62 ACSR HYBRID | 62 | 1+6×3,37mm | 160 | 340 |

| CCSX 1x99 ACSR HYBRID | 99 | 1+6×4,25 mm | 181 | 495 |

| CCSX 1x99 AAAC HYBRID | 99 | 7×4,25 mm | 181 | 422 |

| CCSX 1x159 AAAC HYBRID | 157 | 19×3,26 mm | 220 | 642 |

| CCSX 1×241 AAAC HYBRID | 241 | 19×4,02 mm | 254 | 922 |