Overhead Twisted Cable NFA2XSY-T Application

XLPE insulated twisted cables are applied for specially overhead installationOverhead Twisted Cable NFA2XSY-T Special Features on Request

-

· Oil Resistance

-

· UV Resistance

-

· Flame Retardant Cat. A, B, C

-

· Flame Retardant Non Category

-

· Heat Resistance

-

· Anti Termite

35 – 300 sqmm supplied in compacted circular stranded (cm) conductor shape

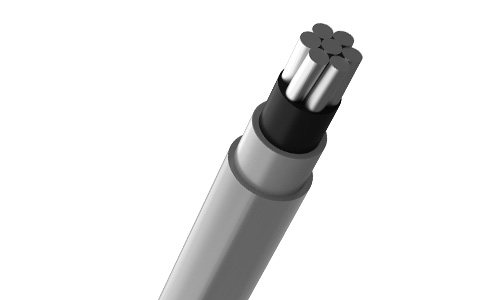

Overhead Twisted Cable NFA2XSY-T Construction

Conductor

Stranded compacted circular alumunium conductors. All internal interstices of three conductor filled with water blocking compound which is specified to prevent ingress of water through conductor during storage, handling, installation and operating of the cable.

Conductor Screen

Extruded semi-conducting compound. Minimum thickness 0.5 mm and the maximum volume resistivity of 5000 ohm-cm at 20°C and 25000 ohm-cm at 90°C.

Insulation

Extruded XLPE with high degree of cross-linking, free form contaminants, air voids and heat resistant by dry cured process.

Insulation Screen

Extruded semi-conducting compound. Minimum thickness 0.5 mm and the maximum volume resistivity of 5000 ohm-cm at 20°C and 25000 ohm-cm at 90°C. The screen is tightly fitted to insulation to exclude all air void and can be easily hand stripped on site.

Metallic Screen

Copper tape applied over the Insulation Screen copper tape with minimum thickness 0.1 mm and maximum 0.3 mm.

Outer Sheath

Extruded black PVC, suitable for exposure to sun-light or other local atmospheric environments and for the operating temperature of the cable.

Overhead Twisted Cable NFA2XSY-T Size

|

NFA2XSY-T 3 x 50/16 + 50 mm2 NFA2XSY-T 3 x 70/16 + 50 mm2 NFA2XSY-T 3 x 95/16 + 50 mm2 NFA2XSY-T 3 x 120/16 + 50 mm2 NFA2XSY-T 3 x 150/25 + 50 mm2 NFA2XSY-T 3 x 185/25 + 50 mm2 NFA2XSY-T 3 x 240/25 + 50 mm2 |

NFA2XSY-T 3 x 50/16 + 95 mm2 NFA2XSY-T 3 x 70/16 + 95 mm2 NFA2XSY-T 3 x 95/16 + 95 mm2 NFA2XSY-T 3 x 120/16 + 95 mm2 NFA2XSY-T 3 x 150/25 + 95 mm2 NFA2XSY-T 3 x 185/25 + 95 mm2 NFA2XSY-T 3 x 240/25 + 95 mm2 |

| Nominal cross sectional area | PHASE | mm2 | 35 | 50 | 70 | 95 | 120 | 150 | |||

| MESSENGER | mm2 | 50 | 50 | 50 | 50 | 50 | 70 | 50 | 70 | 95 | |

| Phase | Approx. Conductor diameter | mm | 6,8 | 7,9 | 9,6 | 11,3 | 12,7 | 14 | |||

| Max. DC Cond resistance at 20 C | Ohm/km | 0,868 | 0,641 | 0,443 | 0,32 | 0,253 | 0,206 | ||||

| Nominal Insulation thicknes | mm | 5,5 | 5,5 | 5,5 | 5,5 | 5,5 | 5,5 | ||||

| Min. DC resistance at 20 C | m.ohm.km | 4400 | 4100 | 3600 | 3200 | 3000 | 2800 | ||||

| Nominal sheath thickness | mm | 2,5 | 2,5 | 2,5 | 2,5 | 2,5 | 2,5 | ||||

| Outer Diameter | mm | 27,1 | 28,2 | 29,8 | 31,5 | 32,9 | 34,2 | ||||

| Steel Messenger | PVC ins. Thickness | mm | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 |

| Outer Diameter | mm | 11,6 | 11,6 | 11,6 | 11,6 | 11,6 | 13,4 | 11,6 | 13,4 | 15,2 | |

| Overall diameter | Approx. | mm | 58,4 | 60,8 | 64,3 | 68 | 71,1 | 71,1 | 74 | 74 | 74 |

| Cable Net. Weight | Approx. | kg/km | 2920 | 3128 | 3455 | 3829 | 4172 | 4357 | 4735 | 4920 | 5136 |

| Standar length per reel | m | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Minimum bending radius | mm | 701 | 730 | 772 | 816 | 853 | 853 | 888 | 888 | 888 | |

| Current carrying | at 20 C | A | 130 | 159 | 193 | 240 | 277 | 277 | 326 | 326 | 326 |

| capacity in air | at 40 C | 110 | 134 | 163 | 203 | 234 | 234 | 275 | 275 | 275 | |

| Short circuit current at 1 sec. | kA | 3,2 | 4,6 | 6,4 | 8,7 | 11 | 11 | 13,8 | 13,8 | 13,8 | |

| AC Voltage test | kV/5 Min | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Calculated breaking force of Steel Messenger | kN | 62 | 62 | 62 | 62 | 62 | 89 | 62 | 89 | 122 | |